R&D – Digital Twin / Simulation Capabilities

Bearing Investigation

Prototyping

High-Precision Stamping & Forming

Bearing Testing & Validation

NVH Analysis

Tailored or Scaled– Always precise

Precision bearings fully meeting customer needs

Competences

Complete Capability. One Trusted Partner.

From concept to movement – mastering every step with precision.

At Durkopp, we don’t just manufacture bearings — we engineer movement from the ground up, starting with the challenging needs of our customers. Our expertise spans the entire process: from initial idea through complex product development to precise production, resulting in long-term performance. This complete capability allows us to turn customer challenges into smart, high-precision bearing solutions that keep the world moving.

Tooling and automated machines development

What drives

the movement

01

R&D – Digital Twin / Simulation Capabilities

Durkopp products follow a world class quality, but product development is key for long lasting and headache-free products. This process can be costly due to engineering hours but also on prototypes. Durkopp relies on decades of experience on calculations and simulations, being able to create a digital twin of your application to anticipate several hurdles and save a lot in development costs. Durkopp has also developed a highly specialized software to calculate bearing service life with highly innovative technics and this assures or confirms the right choice of bearing design to your application avoiding over-engineering.

02

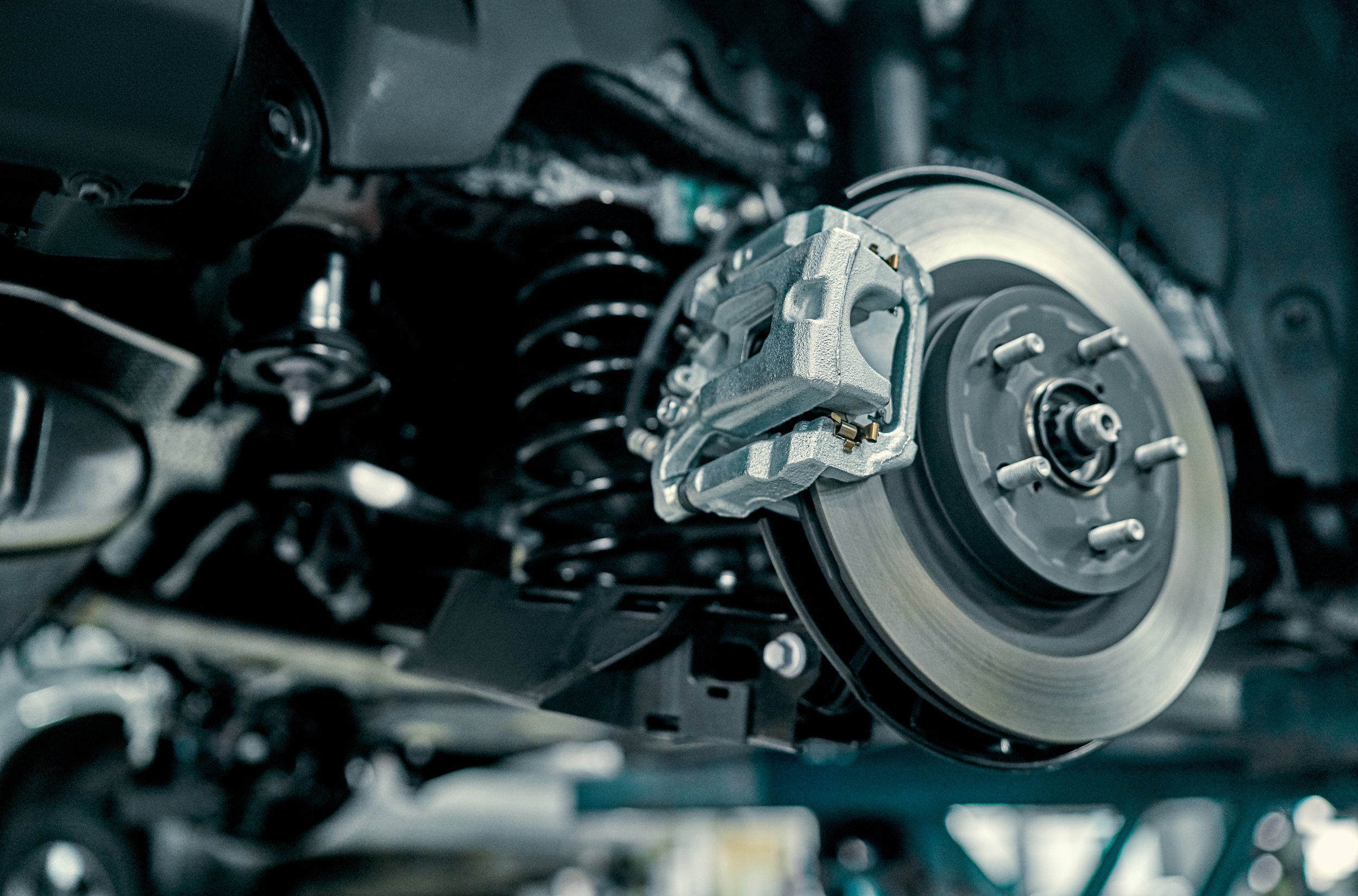

Bearing Testing & Validation

Durkopp operates a wide range of advanced test benches designed to simulate real-world application conditions across multiple industries— including specific application like, for instance, automotive steering systems, aerospace components, brake systems, and high-speed industrial machinery. Our equipment supports testing at rotational speeds up to 20,000 rpm, with capabilities to apply both static and dynamic loads. This comprehensive testing approach enables us to optimize bearing designs for durability, energy efficiency, and application-specific performance, while helping our customers reduce development time and validation costs.

03

Bearing Investigation

To ensure the quality, performance, and functionality of our products, Durkopp relies on state-of-the-art measurement technology and comprehensive analysis methods. High-resolution stereo and digital microscopes enable detailed visual inspections of rolling contact surfaces, while highly accurate measuring devices assess shape and surface characteristics such as roundness, roughness, and profile. In addition, advanced techniques like hardness testing and scanning electron microscopy (SEM) allow for in-depth analysis of material properties.

As classic fatigue damage has become increasingly rare in rolling bearings, other failure mechanisms are gaining importance due to evolving application requirements. With decades of experience and cutting-edge analytical tools—including vibration analysis, metallographic examinations, fault tree analysis, and more—Durkopp’s experts systematically identify the root causes of bearing failures. Based on these insights, we develop targeted measures to prevent future damage and enhance the reliability of your applications.

04

NVH Analysis

Durkopp understands the true meaning of premium noise standards. Our products are developed with tight tolerances and are strictly controlled to guarantee inperceptible noise during its operation. And, beyond that, Durkopp also offers NVH support for your team, helping identifying noise sources and root causes of unwanted vibrations. Performing measurments "in house" and at customers locations.You can rely on Durkopp NVH support to help on noise and vibration issues for quiet equipments.

05

Prototyping

Bringing a product to the market is a great responsability; that's why Durkopp poses great value into testing and evaluating prototypes. In order to control all aspects of this product development phase, Durkopp has a large and very versatile prototype shop, where we can offer speedy and reliable response so you don't lose time while developing your products.

06

Tailored or Scaled – Always precise

Whether for high-volume series production or low-volume specialized orders, Durkopp offers flexible manufacturing solutions tailored to customer needs. Our scalable production capabilities allow us to serve a wide range of industries and project sizes—always with the same commitment to quality, efficiency, and on-time delivery.

07

High-Precision Stamping & Forming

Durkopp manufactures high-precision stamped and formed components in-house, ensuring tight tolerances and consistent quality across complex geometries. Our advanced tooling and process control enable us to meet demanding specifications for both standard and customized parts—supporting performance-critical applications in various industries.

08

Precision bearings fully meeting customer needs

Durkopp produces customized precision bearings based on ISO standards and beyond. We use state-of-the-art technologies at every stage of manufacturing, from raw material to finished product. Our bearings provide exceptional accuracy, quality, and reliable performance with a long service life in both standard and customized high-demand applications.

09

Tooling and automated machines development

Durkopp designs and builds its own tools for stamping, machining, welding, and more—ensuring full control over quality and flexibility in production. This in-house capability allows us to quickly adapt to new requirements and maintain consistent manufacturing standards.

We also develop custom automated machines for our assembly lines and operations, tailored to our specific processes. This integration boosts efficiency, reduces lead times, and supports scalable, high-precision production—reinforcing our commitment to delivering reliable, high-performance bearing solutions.

Let’s build

something

together

Some of our proud partners

Markets

Products

Get in touch

Jürgen Jannaber

Director Technical Centre